As you saw earlier this year, Aptera entered the Validation Phase for its aerodynamic shape at Pininfarina’s world-famous wind tunnel. But that’s not all we’re doing to validate our solar electric vehicle.

Today, we’re excited to take you on a journey through a crucial phase in our mission to make solar mobility a reality — the Validation Phase. In this blog post, we’ll delve into what this phase entails, its significance, and the timeline that will guide us toward building a reliable & safe solar-powered EV.

But first, let’s review the development stages that have led us to this point.

Development Stages leading up to the Validation Phase:

- Concept and Ideation

- Design and Engineering

- System Development

- Computational Fluid Dynamics (CFD) Simulation and Modeling

- Prototyping and Vehicle Dynamics Testing

- Solar Testing and Low-Volume Production

- Supplier Selection and Sourcing

- Manufacturing Planning

Key Steps in the Validation Phase

1. Production of long lead time tools for Aptera’s BinC

As announced in our Monthly Update, over 60% of the essential equipment and tools used in the process of making Aptera’s Body in Carbon (BinC) have been completed and commissioned. These include the stamping dies and post-process tooling used to form Carbon Fiber-SMC with up to 5,000 tons of force into Aptera’s body parts. If you haven’t watched it yet, we highly recommend you take a second to nerd out with us.

These tools have the longest lead times for production and are the most capital-intensive when compared to the equipment and tools for other vehicle zones. Progress here is essential to get Aptera on the road and in your driveways as soon as possible.

2. Production and validation of parts for Aptera’s BinC

With the stamping dies and post-process tooling shown above, the body parts for our production-intent builds, or PI builds for short, are currently being stamped. PI builds are the vehicles that our team will use for further testing and validation over the coming months. They will visually look like a production vehicle and perform much like one too. These body parts go through a thorough validation process, using a Coordinate Measuring Machine (CMM) to inspect for proper thickness and surface tolerance. The parts with green stickers mean they’ve gone through validation, passed the test, and can be used to make our PI builds.

3. Bonding of body parts to form Aptera’s BinC

Once all six main parts of Aptera’s body are completed and validated, they will be bonded together to form the full BinC then the full structure will be validated again for tolerance of the body closures.

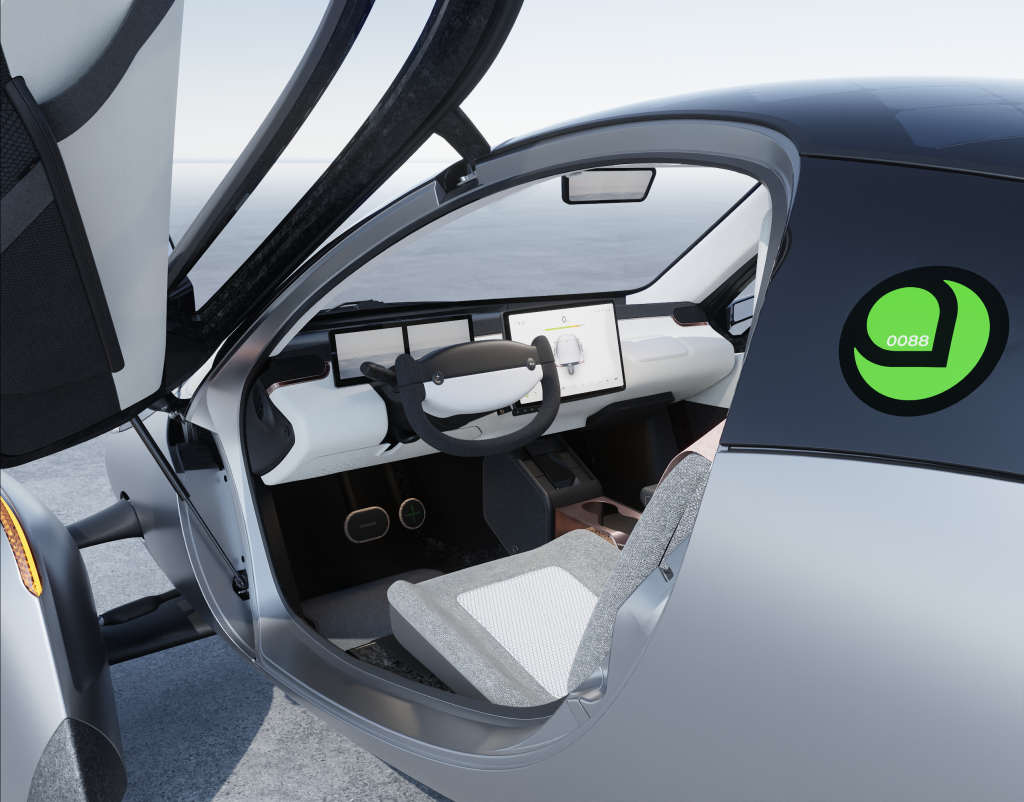

4. Begin progress builds and production-intent (PI) builds

After bonding the Aptera body parts to create a complete BinC, the subsequent steps unfold to produce a full PI build. This process begins by linking the front and rear subframes using the structural battery pack, then integrating this assembly with the BinC followed by the remaining steps involved in our vehicle assembly process shown below.

Our first builds will be progress builds as we add more and more of the production intent components and parts for Aptera. This allows us to ramp up to full PI builds that will eventually have all of our production parts made with production equipment and tooling.

5. Testing and validation of PI builds begin

During the testing and validation phase, our PI builds will undergo rigorous assessments, focusing on various critical components including, but not limited to:

- The suspension and dampeners will be tested to optimize ride comfort and handling dynamics.

- Brake systems will undergo meticulous examination to guarantee precise stopping power.

- Airbag calibration to ensure passenger safety in various scenarios.

- The thermal system will be tested to maintain optimal operating passenger and system temperatures in diverse climates.

- The powertrain and battery will be subjected to extensive trials, evaluating efficiency and durability.

- Software integration will be fine-tuned to optimize vehicle functions, ensuring a seamless driving experience.

6. Safety and crash testing of PI builds begins

In the next phase of Aptera’s validation process, safety and crash testing take center stage. PI builds will undergo a series of comprehensive assessments, including:

- Regulatory compliance checks to ensure adherence to industry standards.

- Quality assurance will be examined throughout the duration of validation to maintain the highest manufacturing standards.

- Vehicle durability and reliability will be rigorously tested to ensure long-lasting performance and peace of mind for Aptera drivers.

- Tuning efforts will fine-tune every aspect of the vehicle’s design to optimize efficiency and overall safety.

- Safety and crash testing will encompass a range of real-world scenarios, reinforcing Aptera’s dedication to passenger safety and vehicle integrity.

7. Manufacturing validation: testing production equipment and assembly lines

During Aptera’s manufacturing validation phase, the focus shifts to ensuring that the production of our solar EVs meets the highest standards of efficiency and quality. This crucial step involves the fine-tuning and testing of production equipment and assembly lines, aiming to streamline manufacturing processes and optimize precision. By thoroughly evaluating every aspect of our production systems, we are committed to delivering Aptera vehicles that are manufactured with the utmost precision for the long haul.

8. Start of production and first deliveries commence

Aptera’s journey will culminate in the moment we’ve all been waiting for as we commence production and prepare for our first deliveries. After years of tireless innovation, the first deliveries will mark the beginning of a new era in sustainable mobility. We will first hand over the keys to our 2,000 pioneering Accelerators, who have supported the start of a brighter, greener, and less destructive future on the road. If you want one of the first 2,000 Aptera vehicles, there is still time — but not much. Check out the header of our website to find out how many slots are left in real-time.

Anyone who invests $10,000 or more until our 2,000th slot is filled can be one of the first to take delivery of their very own Aptera that includes commemorative and serialized markings noting the significance of your revolutionary vehicle.

Through our diligent Validation Phase, Aptera aims to deliver a solar electric vehicle that gets us one step closer to making every journey powered by the sun. We hope you’ll continue to follow along.